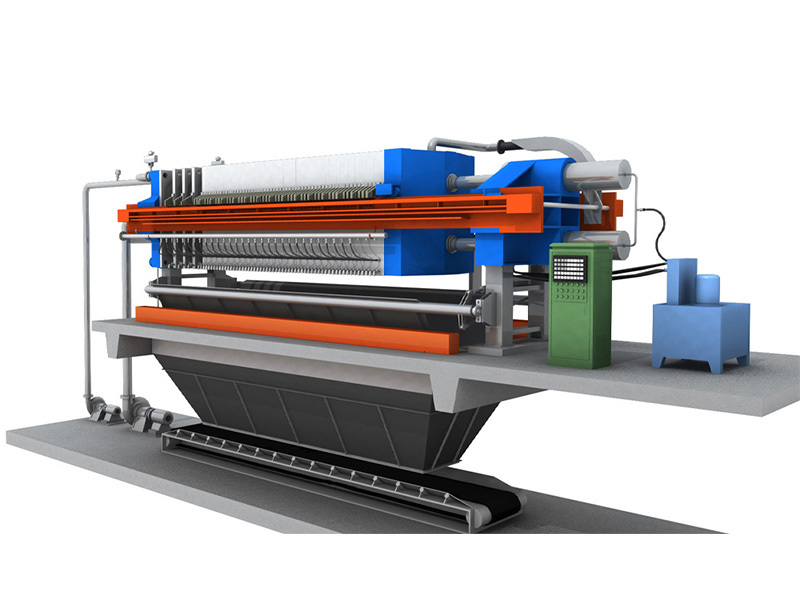

2000-type multi-stage opening filter press

If you need customized machinery, Contact US !

Products Category

- 产品描述

-

Product Introduction

A filter press is a mechanical device that uses a special filtering medium to apply a certain pressure to the object, allowing the liquid to seep out. It is a commonly used solid-liquid separation equipment that can extract the solid from the mixed liquid and achieve the purpose of solid-liquid separation.

Filter presses are widely used in industries such as chemical engineering, pharmaceuticals, metallurgy, dyes, food, brewing, ceramics, and environmental protection.

The filter press manufacturer introduces the working principle of the pressure super to everyone:

The composition of the hydraulic pressing system for the filter press consists of a hydraulic station, a cylinder, a piston, a piston rod, and a Hafland card connecting the piston rod and the pressing plate. The structure of the hydraulic station includes a motor, an oil pump, a relief valve (for pressure regulation), a directional control valve, a pressure gauge, an oil circuit, and an oil tank.

Filtration methods: The filtrate flows out in two ways: open flow filtration and closed flow filtration. In open-flow filtration, a water nozzle is installed on the liquid outlet hole at the bottom of each filter plate, and the filtrate flows out directly from the water nozzle. Dark flow filtration has a liquid outlet channel hole at the bottom of each filter plate. The liquid outlet holes of several filter plates are connected to form a liquid outlet channel, and the liquid is discharged through the pipeline connected to the liquid outlet hole at the bottom of the thrust plate.

Washing method: When the filter cake needs to be washed, sometimes it is unidirectional and bidirectional washing by flow, and unidirectional and bidirectional washing by dark flow.

Dewatering application of filter press

★ As a mature dewatering device, the filter press is widely used in the environmental protection field and has become an important equipment for sewage and sludge treatment.

★ Mechanical dewatering of sludge mainly aims to remove capillary water between sludge particles. The moisture content of sludge after ordinary mechanical dewatering is usually 65% to 80%, and it takes on a cake shape.

★ In the past, the main mechanical dewatering equipment included belt filter presses, plate and frame filter presses, and horizontal screw sedimentation centrifuges. Currently, chamber filter presses, vertical hydraulic filter presses, diaphragm filter presses, and high-pressure plate and frame filter presses are commonly used.

★ When sludge landfill is adopted, sludge dewatering can significantly reduce the space required for sludge accumulation and save the costs incurred during transportation. When composting sludge, sludge dewatering can ensure the smooth progress of composting (generally, sludge with a low moisture content is required during the composting process). If sludge incineration and centralized treatment are carried out, the high sludge dewatering rate can significantly reduce thermal energy consumption and lower the cost of hazardous substance treatment.

★ However, the complex composition, relatively low density, fine particles and often colloidal state of sludge determine its characteristic of being difficult to dewater. Therefore, up to now. Except for the vertical hydraulic filter press, all other filter presses have added a drying process to reduce the residual oil (liquid) rate.

★ The belt filter press has low electrical consumption. The moisture content of the filter cake from the plastic plate and frame filter press is low, but the horizontal screw sedimentation centrifuge has strong adaptability to fluctuations in sludge flow, good sealing performance, large processing capacity and small floor space. In the past, most sewage treatment plants in our country used centrifuges, belt filter presses and plate and frame filter presses, while small-scale sewage treatment plants generally adopted integrated concentration and dewatering machines. Nowadays, chamber filter presses, diaphragm filter presses and high-pressure vertical hydraulic filter presses are commonly used. Their unique technologies make them ideal equipment for sludge dewatering.

About us

Hengshui Jiamei Environmental Protection Equipment Co., Ltd., founded in 2018, covers a total area of 10000 square meters and has more than 100 employees, including 12 engineering and management personnel, and 36 intermediate engineering and technical personnel.

The company has a precision casting workshop, a polymer polypropylene filter plate workshop, a welding workshop, a metal processing workshop, a CNC machining workshop, a pressure filter workshop, a finished product assembly workshop, and a finished product warehouse.

Our company specializes in the production, sales, and technical services of filter presses and accessories. Hengshui Jiamei Company's main products include plate and frame filter presses, box type diaphragm filter presses, quick opening filter presses, filter presses, plate and frame filter presses, filter plates, pressure filter presses, and other solid-liquid separation equipment.

2000-type multi-stage opening filter press

If you need customized machinery, Contact US !

Products Category

Request a Quote

We will contact you within one working day. Please pay attention to your email.